Table of Contents

Distribution box construction

Introduction

Presentation of the advantages of distribution box for rural gravity fed water supply is quickly presented in Doc n° ST3-S01 “Presentation of PROCEED general standards”. The hydraulic involved in distribution box is presented in Doc n° MF4-S40 “Crest flow in distribution box”

Dimensions of distribution box

All the details can be found in the drawing Drawing n° MF4-D43:

| Inside Length and Width of Distribution Box adapted to the number and type of outlet pipes1) |

|---|

| L (cm) = 30 + O x 15 With O : Number of Outlet |

| W = 60 cm for inlet ⌀ ≤ 50 mm and W = 80 cm for inlet ⌀ > 50 mm or double outlets |

Example:

Find details about the DB in the sketch map of the network:

- Number and diameters of outlets are written inside the DB sketch.

- Inlet diameter is the same as the DB upstream pipe. If the pipe has different diameters, the inlet diameter is the same as last section of it:

- Length L = 30 + 4 outlets x 15 = 90cm

- Width W = 60cm because inlet ≤ 50mm (Last section of pipe n°3 = 32mm)

- H is the height of the DB bottom slab from natural ground (given by designer in the sketchmap)

For the width there is an exception with double outlets:

Foundation & PVC pipes

Foundation excavation for the raised DB is 60cm minimum to ensure pipe protection and must be compacted well. Find details about foundations here Doc n° MF4-M15 “General construction standards” § Structures foundation. Once the ground is compacted arrange overflow, inlet and outlets on the ground, here is an example all this pipes are PVC):

When the sketch map indicates an inlet as 12.5 or 16, this must be understood as a half pipe. 12.5 corresponds to half of 25 mm and 16 corresponds to half of 32 mm, use Ø25 and Ø32 mm pipes respectively (see the next chapter for more details). So for this example you need to prepare the following PVC pipes: 1 DN50 for the inlet, 1 DN75, 1 DN32, 1 DN25 for the outlets and always a DN75 for the overflow. On the inlet, a drainage tee have to be installed (to allow cleaning operations):

Then a masonry foundation must be built in the center of the foundation with random rubbles and 1:4 mortar. The calculated dimensions in previous chapter must be used. The pipes must be installed inside the masonry with the following dimensions (using the same example of Zaree DB):2)

All pipes must be installed on the ground to ensure a good protection at the end of the construction. Only the washout can be installed higher (30cm) to avoid installing a long line to the spillage point if the natural slope is not high enough. All PVC pipes must be 40 cm higher than the top of the masonry to allow for casting of the bottom slab.

Here under is the assembly that allows drainage of inlet, outlets and overflow for DBs with H>0.5m:

See Doc n° MF4-M15 “Standard construction items” § Connect PVC with HDPE fitting for a methodology to safely connect a HDPE fitting on a PVC pipe.

Bottom slab casting

Before casting the bottom slab, glued fitting for PVC pipes must be installed as follow:

In this example, one pipe is a half cut pipe indicated by this symbol (for 12.5 and 16):

For outlets cut pipes, it is very important to realize a clean 90° cut to respect the distribution design of the DB. Use a small piece of PVC pipe the same size as a support for the saw:

Arrangement for large pipes:

In cases where large pipes are required (DN >75), a reducer can be used to save on costs and reduce the number of fittings required. The reducer must be installed at the end of construction, just above the bottom slab, to maximise the length of the large-diameter vertical pipe (chute).

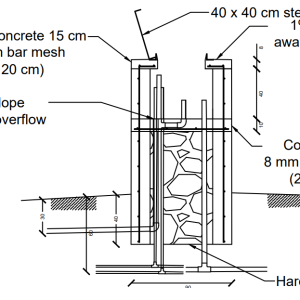

To prepare slab casting 8mm rebar 20x20cm mesh must be installed with iron wire around the masonry in the middle of the 15cm thick walls and 3 cm above the masonry for the slab. See dimensions below:

Before casting of the slab, pipes should be protected from entrance of concrete with iron wire and plastic bags:

Then bottom slab can be cast with framework (wooden or metal sheet) around the masonry that allows a 15cm thick wall around the masonry. Good practice standards about concrete handling and production can be found in Doc n° MF4-M13 “concrete production methodology”. Concrete (1:2:3) casting must be stopped when the bottom slab is at least 10cm thick or adjusted on the biggest tee (required for DN75):

Walls and top slab casting

Framework that has been used for bottom slab casting must be used as the outside framework for the walls and top slab (do not remove it after first casting). Wait 72 hours (with daily watering) before installing wooden inside framework respecting a 40cm inside height of the DB and 15cm thickness for the walls. Then walls can be cast with 1:2:3 concrete.

Wait 72 hours (with daily watering) then prepare the top slab casting, bend the vertical rebar as follow:

Define door dimensions, up to 5 outlets door inside dimensions is 40x40cm, more than 5 outlets door must be 55x55cm. Prepare inside formwork for the top slab keeping in mind that all the pieces of formwork will have to be removed throw the door. Then Install top slab rebar mesh with a space for the door that will be 10cm above bottom slab (DB inside height + 15cm top slab thickness):

Details for door installation can be found here: Doc n° MF4-M15 “General construction standards” § Metal door installation.

Cast the walls with 1:2:3 concrete, stop when top slab is 15cm thick. Make sure that the top slab has a 1% slab toward outside:

The framework must be kept installed 7 days and the structure have to be watered every days.

Finishing work

Make a mortar slab finishing to have the slab sloping towartd the washout

The overflow/washout spill point have to be protected by a concrete structure. For details about that structure consult Doc n° MF4-M15 “General construction standards” § Washout erosion protection structure. The level of all the outlets have to be checked because the accuracy of the yield distribution depend on it. Every level should be +/- 1mm the same, check using a spirit level:

Visual inspection on the crest flow of each outlet have to be done as a second level check, they should all look the same:

To ensure that the inlet flow disturbs the water surface as little as possible, a tee must be placed on top of the inlet. The tee should be placed unglued at the same height as the outlet pipes in order for the water to flow without drop and the air to escape without making bubbles

Outlet

Water level

Inlet

Water Flow

Air Flow