Table of Contents

Water Point Construction

Dimensions of water Point

Water point includes:

- Fountain/tap stand

- Wash Table

- Cattle trough

Construction schedule

Before starting any work, for open flow WP, check the yield arriving by inlet HDPE pipe versus design requirement (on sketch map). For closed WP, the water point can be constructed at the same time as the reservoir, after check of the yield arriving at the reservoir.

The position of the water point shall be decided first. The elevation difference between the slab of the reservoir and faucet of the water point should not be less than 50 cm. Pipe between reservoir and fountain is only backfilled after testing it.

- Foundation excavation and hard core packing can be done at the same time as reservoir foundation work

- The WP slab construction can continue and finish while the reservoir wall is curing (5 working days)

- The WP construction is finalized while the reservoir top slab is curing (5 working days)

Orientation of overflow pipe in different scenarios

Before starting any work, construction expert has to fill the WP configuration format during construction transfer visit, refer to Doc n° MF4-M71 “Pipeline protection methodology” § Construction transfer field format. This document is meant to help the contractor and the supervisor to respect the following rules described in chapter 3 & 4:

Water point Configuration

- The orientation of the WP is determined with the construction expert based on topography and slope conditions and convenience for the community, by filling the field format and pegging the locations.

- The door direction / position is toward the faucet for single faucet and for double faucet it will be perpendicular to the faucet. Whenever possible the door opening shall be on the side of the wash table and opposite to the drainage ditch. Care has to be taken regarding access from the main road.

- The direction of the drainage canal should be towards the downward slope.

- The overflow pipe from the WP to the cattle trough should not cross the wash table. The cattle trough should be downstream of the water point and wash table. The minimum distance between the cattle trough and WP must be 12m.

- The wash table can be constructed at any side of the WP depending on the suitability of the land as long as it respects the above conditions. The minimum distance between the WP slab and wash table is 1m.

- Water point and reservoir overflow must be connected with the cattle trough except if the distance between reservoir and cattle trough is more than 50m (that must be avoided whenever possible).

- The contractor must accept the water point configuration as set out and pegged before the work and will be accountable to follow that configuration.

- Below 2 options are shown as example and the best option will be selected and approved at site level by the construction expert:

Pipe protection

A very important point to consider before digging the structures foundations is pipe protection. The pipe from reservoir or DB to WP, from WP to cattle trough and from cattle trough to overflow evacuation should be buried and protected according to the following rule:

| Depth of the pipe trench | Nature of protection |

|---|---|

| Over 60cm | Simple soil backfilling |

| Between 30 and 60cm | Dry masonry protection (big stones) |

| Under 30cm | Concrete hump on the pipe |

The following drawing represents the ideal scenario if ground and the natural slopes are managed well:

Foundation

For details about foundation construction refer to Doc n° MF4-M15 “General construction standards” § Structures foundation

After the excavation of the foundation, the drainage PVC pipe must be installed before the masonry work and hard core stone filling because they have to lay on the ground. For a single faucet, install a DN75 PN10 PVC pipe with an elbow at least 1m up and 1.2m towards the drain. For a double faucet, add a 1m pipe and Tee going 1.5m towards the drain:

Care must be taken to keep the PVC pipes vertically aligned during the lean concrete casting:

The cattle trough or washout location must be defined before the foundation work to respect the 1% minimum slope of the PVC pipe. It is even better to work on cattle trough foundation at the same time.

The trench can be overdug to respect this important slope.

Slab casting

Dimensions and details can be found in drawings n° MF4-D60, MF4-D61 for single faucet and n° MF4-D62, MF4-D63 for double faucets. Good practice standards about concrete handling and production can be found in Doc n° MF4-M13 “concrete production methodology”.

Slab rebar preparation before casting for single and double faucets (tie the bars with wire):

The GI water inlet pipe must then be installed and tied on rebar for easy installation. Class B GI pipes are mandatory. The list of components for these pipes are:

It is recommended to use the following assembly at the end of GI pipe for the drainage plug. The 2 welded pieces of steel inside the concrete block any rotation of the pipe when removing the plug to avoid leakages inside the slab that are difficult to repair:

When rebar and GI pipes are installed, the 10cm thick slab is ready to be casted with formwork. Care should be taken to maintain the verticality of the GI pipe during slab casting. There are 2 important characteristics to respect during this casting:

- The fountain rebar frame must be attached to the slab rebar mesh for the strength of its structure. To achieve this, leave an opening in the slab to do it after. Details about fountain rebar frame are shown in drawings n° MF4-D65.

Opening left inside the slab for fountain rebar frame (single and double faucet):

- The slab has a 1% slope towards a surrounding channel, which in turn has a 2% slope towards the evacuation channel. The slab must be cast in monolithic concrete with a smooth surface meaning:

- It must be cast in a single day (with trowel or using smooth timber as formwork)

- All its components must be in concrete (slab slope, surrounding and evacuation channel)

- Only the opening to attach fountain rebar can be left open

- Only sprinkling of cement on fresh concrete is allowed to create a smooth surface: mortar is absolutely forbidden

Precise dimensions of the slab are given in drawings n° MF4-D60, MF4-D62:

After the casting, slab should be watered 2 times a day at least for seven days and covered with jute bags or banana leaves. The site supervisor will test slope by pouring water everywhere on the slab and the drainage channel. All the water should be drained to the spillway, no puddle must be left on the slab:

Fountain stand casting

The first step is to tie the rebar fountain frame inside the opening of the slab. The dimensions to of the frame are as follows (extract from drawings n° MF4-D65):

Once the rebar frame is installed and the dimensions checked, the mould should be assembled around it, and the inside faces that will be in contact with the concrete should be lubricated with oil (burnt oil is ok). It is recommended to adjust the height of the PVC pipe at this step to 55cm from the slab (it can be after but it is more difficult). Once the PVC pipe is adjusted, protect it by stuffing with plastic bags inside it to avoid concrete going inside. After installation, check that:

- Rebar has a minimum clearance of 1.5cm with the mould

- Check the level on the jerrycan seat with a spirit level

- All bolts and nuts are installed

- Inside dimensions should also be checked (see below for single and double faucet a +/-1cm tolerance is allowed):

When the mould is installed and checked, concrete can be cast using a GI pipe to vibrate inside and a wooden hammer for outside (refer to good practice for concrete handling in Doc n° MF4-M13 “concrete production methodology”).

A bowl shape must be formed during casting around the PVC pipe (~Ø10cm).

3 small rebars Ø6mm must be cast above the PVC drainage pipe to prevent big rubbles from getting inside.

A recommended method is by using a coffee pot, 3x6mm rebar and cutting in the PVC pipe before fountain casting:

After casting, keep the mould in place for 7 days, water the top of the fountain every day and cover with jute bags or banana leaves. The GI water inlet is connected to the HDPE pipe with a connector cast in a concrete protection. This is the only case where a connector is allowed to be cast in concrete. A second connector must be install upstream as soon as the depth reaches 40 cm. The first meters of the HDPE pipe have to be covered by stone until the soil protection is deeper than 60cm as detailed in chapter 5:

Water point fence characteristics (mandatory before final payment):

- All WP must be fenced with local materials barbed wire or CIS

- Inside the fence must be paved with stone

- The fence must have a lockable door

- The spacing of main poles must not be more than 60cm

- Poles are placed in the ground at minimum 40cm depth and 2m above ground

- Corner poles must be attached with a diagonal wood support

Responsibilities:

Wash table

For details about foundation construction refer to Doc n° MF4-M15 “General construction standards” § Structures foundation.

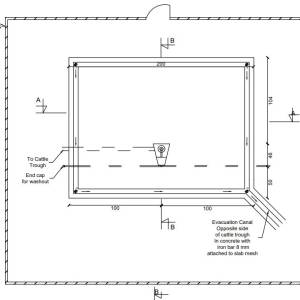

To cast the wash table slab use the same method described in chapter 6 for the 3 x 2.2m dimension (with monolithic concrete for the slab slope, surrounding channel and evacuation channel):

The wash table rebar frame must be attached to the slab rebar mesh for the strength of its structure. There are 2 recommended solutions to achieve this, attached the frame with wire before slab casting or leave an opening in the slab to do it after.

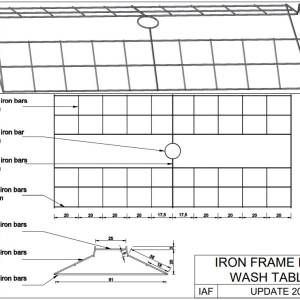

The table frame must then be tied to the vertical mesh. For details about wash table rebar frame refer to drawings n° MF4-D66:

Once the rebar frame is installed and the dimensions checked, install the drain pipe. Provide a straight (without elbow) 50 mm PVC pipe slanted drain from the center of the top of the wash table to the edge of the bottom of the wash table stand which will drain the washout water to the drainage channel:

Then the mould should be assembled around it and the inside faces that will be in contact with the concrete should be lubricated with oil (burnt oil is ok). After installation check that:

- Rebar has a minimum clearance of 1.5cm with the mould

- Level on the four corners is correct (measure with spirit level)

- All bolts and nuts are installed

> When the mould is installed and checked, concrete can be cast using a GI pipe to vibrate inside and a wooden hammer to vibrate outside (refer to good practice for concrete handling Doc n° MF4-M13 “concrete production methodology”).

Form 2 separate compartments during the casting, the 2 slabs must have at least a 1% slope toward the centre drainage pipe. The slope, the surrounding ridge and separating ridge must be cast in concrete at the same time as the whole washable casting (monolithic), no mortar is allowed. Sprinkling cement is only allowed to obtain a smooth finish (if it is done the same day).

After casting, keep the mould installed for 7 days, water every day the top of the table and cover with jute bags or banana leaves. To finish construction quality should be tested by pouring water everywhere on the slab, the drainage channel and the table. All the water should be drained to the spillway, no puddles.

Cattle trough

For details about foundation construction refer to Doc n° MF4-M15 “General construction standards” § Structures foundation. Cattle trough can be 1, 2 or 3 meters long, the need must be decided with the community before construction.

After the excavation of the foundation, the drainage DN75 PN10 PVC pipe must be installed before the masonry work and the hard core stone filling.

After the foundation, slab and trough structure have to be cast at the same time with the mould. Here is the detail of the rebar structure (only 8mm diameter) to prepare and install on 2-3cm crushed aggregate used as a spacer:

Reinforcement details for the cattle trough of length 3m:

Water inlet(s) should be installed following these rules:

- Water inlet(s) should be installed 1cm above the foundation lean concrete

- The cattle trough is connected to the fountain (75mm PVC pipe) and to the overflow of the reservoir (50mm) when possible (distance between cattle trough and reservoir is less than 50 m)

- It is better to place the 2 inlets (reservoir overflow & WP evacuation) separately into the cattle trough wall rather than to use a Y connection:

Then the mould should be assembled around it and the inside faces that will be in contact with the concrete should be lubricated with oil (burnt oil is ok). Respect a minimum slope of 2% of the bottom of the trough towards the washout. After installation check that:

- Rebar has a minimum clearance of 1.5cm with the mould

- Level on the four corners is correct (measure with spirit level)

- All bolts and nuts are installed

When the mould is installed and checked, concrete can be cast using a GI pipe to vibrate inside and a wooden hammer to vibrate outside (refer to good practice for concrete handling Doc n° MF4-M13 “concrete production methodology”).

After casting, keep the outside mould installed for 7 days, remove the top mould after 24 hours and fill with water, keeping it filled for 6 days. To finish construction, quality should be tested by pouring water in the trough. All the water should be drained to the washout, no puddles. The area should be as follows:

To finalize construction, the overflow/washout must lead to a suitable area to drain water (canal) and be connected to an erosion protection structure. For details about that structure refer to Doc n° MF4-M15 “General construction standards” § Washout erosion protection structure